Tuesday, 17 June 2014

Tuesday, 27 May 2014

Assignment 5

For the fifth assignment for BENV2426 i wanted to create and model a natural system. Initially i wanted to create the natural system of a tree. However, due to the accessibility and availability of 3d printing I decided not to model a tree system for the fifth assignment.

Researching at a smaller scale i decided to then look at different leaf types.

Taking inspiration for different leafs, I really liked the form and shape of a Maple leaf.

After doing some research of Maple leafs i decided that this was the natural system i was going to recreate and laser cut for my final assignment.

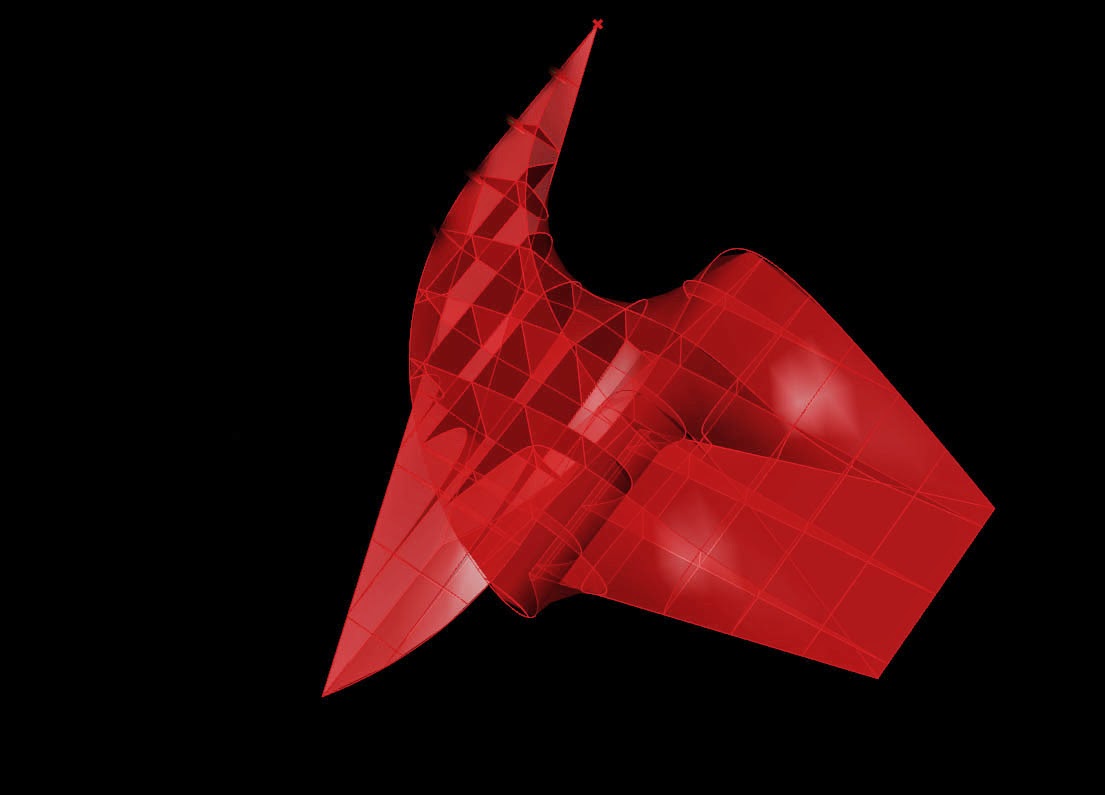

The image below was found on the 'Grasshopper3D' website.

I intend to recreate the below image.

The image below was found on the 'Grasshopper3D' website.

I intend to recreate the below image.

______________________________________________________________________________

Due to the sizing limits of the laser cutter i had to split my model into two halves.

below are some images of the forms progression and overall view of the script, the final script will be shown at a smaller scale.

below are some images of the forms progression and overall view of the script, the final script will be shown at a smaller scale.

Production of Assignment 5

Assignment five has definitely been the most enjoyably assignment for me. From scripting the whole assignment from scratch in grasshopper i have learned a great deal about grasshopper, its potential. However, i have also gained a great insight into parametric design and the fabrication aspect and process.

Below is an image of one of the final leafs

Below is the script for the leaf shape and veins

Below is an image of one of the final leafs

Below is the script for the leaf shape and veins

Below is the script for the leaf pattern

Monday, 26 May 2014

Assignment Four

Brief: Design and produce a 3D model consisting of minimum 2 separate parts. The parts can be constructed using one or two combination manufacturing process (e.g. lasercut parts and 3D printed parts). The model must occupy a bounding box with dimensions: 204mm x 226mm x 200mm

___________________________________________

For

the fourth assignment for experimental modelling, I wanted to create a 3D

geometry that was interchangeable and could be assembled and recreated

into different forms.

The

main idea around creating square like shapes that can be assembled into differing

forms was derived from the idea of an architectural wall that can be changed

and transformed before, during and after instillation. The main idea centred on clients having the

ability to change wall patternations and designs.

The

idea also applies to furniture and design ornaments. The user has the ability to change and

personalise their furniture and ornaments.

In order to achieve this is decided to create forms like the

ones below. It was important that the

base shape was a tessellating pattern to allow for a more ability in creating

many different forms. Below are some images

of what I wish to achieve.

I will be laser cutting the shapes to maximise the potential

for etching patterns and symbols.

Tuesday, 29 April 2014

Assignment Three Final

During the process of

laser cutting my waffle, i realised that i had made my slits

1mm too small! Also after laser cutting my waffle i was

made aware of some faults in my script and design!

The great thing about laser cutting and the facilities at UNSW is that they are

free and available to experimental modelling students. Laser cutting is a great way of prototyping

and through the mistakes made on this assignment, will help me with future

assignments.

When I recut my waffle I found that box board was very flimsy and would break and was fraying!! So for the exhibition i will recut the waffle on ply wood

_________________________________________________________________________________

Subscribe to:

Comments (Atom)

.jpg)